X Prize contenders prepare for the Knockout phase of the competition.Courtesy X Prize Foundation

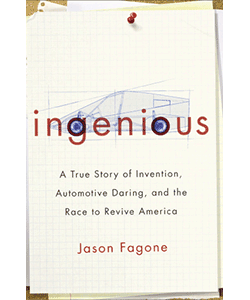

Out next week, journalist Jason Fagone’s new book, Ingenious: A True Story of Invention, Automotive Daring, and the Race to Revive America, takes us for a ride-along on the fringes of efficient vehicle design, as dozens of rivals compete for a share of the 2010 Progressive Insurance Automotive X Prize’s $10 million purse. Their holy grail: a (relatively) safe and practical long-range vehicle that can get 100 mpg or the voltaic equivalent.

With his keen eye for scene and character, Fagone follows a handful of contenders, from a scrappy Virginia startup to some endearing Illinois barnyard tinkerers, to a talented crew of West Philly high schoolers as they run into (metaphorical) roadblocks en route to the finals. In addition to hearing their eye-opening takes on transportation, and learning what goes into creating a radical new vehicle—from scratch, in many cases—we drive away with a deeper perspective on Detroit, whose staid modern offerings, by and large, have barely bested the mileage of a Model T.

Fagone had some interesting things to say about the great race and what came of it—you can read our chat here. But first for a taste of the book: The following excerpt, courtesy of Random House (which includes the Crown imprint) introduces us to one of Fagone’s most effusive and enjoyable characters, Oliver Kuttner, whose unique strategy involved building a gasoline car so lightweight and efficient that it makes your Prius look like a Humvee. Enjoy the ride.

*****

The Abyss of Lightness

Lynchburg, Virginia, March 2010 — Oliver Kuttner digs into a pocket of his jeans and plucks out something metallic that he raises up to the light. He places it in my outstretched hand.

“Two-tenths of an ounce,” Oliver says.

The object is an inch-long piece of pale aluminum with a hexagonal shaft and a circular ring. A lug nut. A lug nut holds a wheel to a car. Carwise, you can’t get more fundamental than a lug nut. It feels as light as a cough drop.? “Cool, right?” Oliver says, beaming.? He takes a step backward and studies my face for a reaction.

Oliver is an imposing figure, 6-foot-4 and 240 pounds, with large green eyes. In college he rowed on the crew team—the five seat in an eight-man boat, the brute shoveling coal into the furnace. His white-collared shirt says Edison2 above the heart, and his slightly bulging stomach pulls the shirt taut where it’s tucked into his jeans.

We’re in a workshop. White walls, no windows. The building used to be a Dickies jeans factory, years ago, and this is a lightly renovated patch of the old factory floor—a large, high-ceilinged, squarish room. It smells a bit like a scorched metal cooking pot. Layers of noise: blasts of power tools, snippets of conversation, a radio playing quietly underneath.

Over on the far wall, next to a trash can full of curlicue-shaped metal shavings, a man in safety goggles is bent over a metal lathe. Its whine overpowers the chatter of the nearby mechanics, who are dressed all in black. I can’t really figure out what’s going on; it’s like there are pieces of three or four different types of companies smushed into this one room. Depending on where I look, I see a hip architecture firm, a race shop, a used-car dealership, or a machine shop. Classic sports-car posters hang on the walls next to 3-D computer drawings the size of architectural blueprints, and not far from the guy at the metal lathe, two men type on laptops at desks. Hydraulic hoses snake up the walls like vines, and sparks from a welder sizzle onto the lacquered pine floor.

Flickering in my peripheral vision are the Edison2 cars themselves, four of them, spread across the floor in various stages of assembly. Three are still just frames of steel tubing, lacking bodies. The fourth, clad in silver-colored fiberglass, looks like a real, drivable car. The car’s profile changes drastically according to the angle of view. From the top, it’s roughly a diamond. From the side, it’s a bird skull with a pointy beak. From the front, it’s Darth Vader’s pentagonal helmet. The wheels are housed inside pods that jut out from the body. The engines—small, extensively modified motorcycle engines that run on gasoline—are mounted in the back instead of the front.

Oliver turns to a nearby storage rack, where he picks up a length of aluminum pipe—another small, humble car part. He tosses the pipe in the air and catches it with a smack. “It’s just stupid,” he says.

“Stupid light?” I ask.

Oliver nods vigorously. He starts talking about how much money he has spent to make these parts. They’re all custom, he says; almost nothing in the car has been bought off the shelf. His engineers designed the parts from scratch and had them machined out of billets—solid blocks of aluminum and steel. “It’s the only way you can do it without building casting molds,” Oliver says, “and casting molds are quite expensive.” In the future, he says, when he goes into production and makes 10,000 of each part at a time, the cost will go down. A $50,000 wheel will become a $200 wheel; a $65 nut will become a 20-cent nut.

The nut is significant, he explains, because it weighs one-tenth to one-third of a typical nut. I gather that Oliver wants me to appreciate the extravagance of how much money he has spent to shave off such a miniscule amount of weight. There aren’t a lot of lug nuts on a car—16 to 32, depending on its size. His custom lug nuts might reduce the overall weight of the car by a pound or so. But the fact that he would go to the trouble of reinventing the common lug nut just to shave off a measly pound shows how far he’s willing to go to prove a concept.

“General Motors and BMW and Ford, they all have light-weighting programs,” Oliver says. “In the process, they figure out how to take 3,600-pound Corvettes and make them into 3,400-pound Corvettes, which is a good thing.” The major automakers can make cars lighter around the edges. But each of the four cars now under construction in the Edison2 shop will weigh less than 800 pounds when finished. The lightest car on the market, the Smart Fortwo, weighs 1,800 pounds. Oliver has taken lightness to a new extreme. He says he finds this idea hard to get across to people just learning about the car, because the automakers have “poisoned the water” with their lax commitments to lightness.

“Imagine being in the ’20s, and an airplane company says, ‘We’re going to go to space,'” he says. “And other people say, ‘We’re already going to space, we fly up to 6,000 feet.’ You have to explain that what you’re really doing is actually going to the place where there’s no gravity.” Oliver adds, “For most people it’s very difficult to understand until you hold something like this,” and nods to the lug nut in my hand.

Every once in a while, you come across the sort of supremely gifted salesman who only needs a few minutes to drag you into his orbit like a rogue sun. Oliver strikes me as one of these guys. He obviously knows how to split the world into people who get it and people who don’t and to make you want to stand on the side of the angels. I’m sure he’s pressed lug nuts into dozens of hands before mine. (I learn later that he carries around up to 20 lug nuts at once; whenever he leaves for a conference, he runs over to the shelf and reaches into the lug nut bag and stuffs them into his jeans and jacket pockets, forcing the mechanics to scrounge for lug nuts to put on the cars.) But even as I’m thinking this—trying to stay skeptical, trying not to get swept up by the momentum of the pitch—I’m also thinking that the thrust of what he’s saying is pretty intuitive. And also kind of refreshingly ungadgety.

Lightness! A cardinal virtue of human vehicles going back to the covered wagon, the chariot, the dogsled. Others interested in shaping the future of the car like to talk about electric vehicles, hybrids, charging infrastructures, upgrades to the electrical grid, and Google’s prototype robotic cars, which are so smart they can drive themselves. But Oliver seems to be after something more fundamental. Use any type of energy you want, he says—gasoline, electricity, hydrogen, compressed natural gas—but make the car light, very light, and you’re ahead of the game. Simple physics. The less mass, the less force you need to accelerate it. Isaac Newton’s Second Law of Motion.

At first, this is what I think Oliver is getting at with the lug nut: He has made a superlight car, therefore a superefficient car (even though it runs on gasoline, not electricity), and he has done it by making a bunch of custom superlight parts—not just the light lug nut but all these other parts on the racks of the shop. Light hubs and light bearings, light wheels, light shifter knobs, light seat rails. But the story turns out to be more complex than that.

Because if you took all these light parts and put them into a normal car, it wouldn’t work. The car wouldn’t be strong, wouldn’t be safe. Oliver’s car can be 800 pounds because it has a unique and somewhat alien architecture that allows it to be that light. The big idea, the major piece of new technology, is a custom suspension—the part of the car that controls vertical movement, absorbing bumps and giving you a comfortable ride on potholed roads. In a normal car, the front and rear suspension takes up a lot of space, the various components sprawling out horizontally and vertically. Oliver’s engineers have figured out how to confine the mechanism that allows for vertical travel fits entirely inside the wheel, along with a damper and the brake.

This may sound like a minor change, but it’s not. The suspension is one of those things in a car that other things are built around, determining the course of the overall design, bounding its potential. It is to a car what a river is to a city. Edison2 yanks up the river, reroutes it, and builds a new city on its banks. In-wheel suspensions have been tried before, in limited ways, but no company has ever used the technology as the starting point for a new kind of car.

Putting the suspension in the wheels eliminates the need for a lot of the structure, the steel you’d normally need to enclose the suspension and to attach it rigidly to the rest of the car. And once you eliminate those structures, the other pieces of the car can be lighter. Imagine you’re a 300-pound person who goes on a diet and loses 100 pounds; you can suddenly get by with a lighter chair, a lighter bed, thinner floors. If it were biologically possible, you could redesign your ankles. The fact that one piece of the car is light means that the next piece can be light, and the next piece. And when Oliver and his team go to assemble the puzzle of the car, fastening lightness to lightness, they end up with something so elemental, so irreducible, that Oliver feels it’s explicable only by a sort of Zen koan: “The car is light because the car is light.”

He calls it the Very Light Car.

ACTUALLY the first prototype of the Very Light Car, assembled in early 2008, turned out to be too light. It looked like a dune buggy. It had two seats, a bare, steel-tube frame with no body, and a single-cylinder Yamaha motorcycle engine. It weighed 367 pounds.

Oliver decided to try a little experiment. He climbed into the dune buggy and steered it onto a public road in Charlottesville, Virginia, where he lives, an hour northeast of the workshop. He hit the highway and opened the throttle, gunning it to 80, his crown of curly gray hair whipping in the breeze. Oliver used to drive professionally in sports-car endurance races, and over the years he has built several high-end racing prototypes. He would have driven the Very Light Car prototype faster but he was already on probation for having too many speeding tickets.

“We went to the absolute edge,” he says, “to the abyss of how light you can make it.” It was strictly an exercise: What was the minimum weight of a car that was viable for real roads? Now that Oliver had his answer, he decided to make the car heavier, because a 367-pound car is just as dangerous as a motorcycle. So Oliver more than doubled the weight, adding two seats and increasing the car’s safety, which is the main challenge in making a light car. How do you take out weight and still protect passengers in a crash?

In the main room of the workshop, Oliver grabs a printout from a table and moves nimbly through a pair of 10-foot-high double doors. In an outer hallway, the bare-metal frame of a Grand-Am race car is nestled against a wall next to a potted plant. The front of the car is crunched and mangled.

Oliver holds up the printout. It shows a line on a graph. At one coordinate, the line spikes sharply upward. He says it came from the Grand-Am car’s black-box recorder, recovered after a crash. During one split second of impact, the driver was subjected to a staggering 80 G’s—a sensation of gravity 80 times stronger than that found on Earth. Fighter pilots black out at a sustained nine G’s. “The guy unbuckled and walked away,” Oliver says. “These race cars are not fragile cars. They are purpose-built machines of war.”

Oliver says that, in racing, cars have to be light so they can win, but they also have to be strong so drivers can survive high-speed crashes. Think about Indy car crashes you’ve seen on TV; the wheels shear off, and the cars, with their pointy front ends, bounce off walls and other cars at all angles. Traditional cars are boxes with flat surfaces designed to crumple in a crash. But the Very Light Car should skitter away from many kinds of collisions instead of engaging. “Those wheels are essentially side bumpers,” Oliver says. “The car is designed in an accident to behave like a judo fighter, a karate fighter. In most accidents, you will end up deflecting.”

He hasn’t done a crash test yet to prove his theory—right now he can’t afford to destroy a prototype—but he plans to. Lately he’s been studying crash-test vehicles from major automakers. To the left of the damaged race car are the front halves of a 2005 Smart, a car manufactured by Daimler AG, which also makes Mercedes-Benzes, and a 2007 Scion XB. Both are totaled, their windshields spidered and cracked, their frames pretzeled. Oliver convinced a nearby crash-testing facility to give him a couple of its wrecks. “You die in a Smart every time you crash head-on,” Oliver says. “I don’t care what Mercedes says.”

THERE’s a plan here—a plan to make all of this real, to get Very Light Cars into driveways and onto roads. I’ll come to understand the scope of it over the next several months. It may be crazily ambitious, but it exists, and it goes well beyond the X Prize. That much is clear today in the shop. Oliver wants to win the contest and the money. But he also wants to be a company that endures well after the Prize is over. He wants to build something that lasts. And lately, he says, he’s been thinking a lot about how to do that.

An obsessive reader of automotive history, he knows all about the guys who’ve come before him, the dreamers and strivers who’ve tried and failed to breach the heavy iron door of the market: Preston Tucker, the master salesman who built 51 prototypes of a revolutionary car, the “Tucker Torpedo,” in the late 1940s, only to see his young company crushed by a stock-fraud investigation by the Securities and Exchange Commission; Henry J. Kaiser, the famous dam-maker and World War II shipbuilder, who started manufacturing his own cars in 1946 and lasted only nine years, despite all his wealth and power, tallying about 800,000 cars in the end; John DeLorean, the former General Motors engineer who managed to crank out about 9,000 eponymous sports cars at a factory in Northern Ireland in 1981 and 1982 until he ran out of money and tried to raise funds by discussing a cocaine-trafficking deal with a guy who turned out to be an FBI informant. (At trial, DeLorean was cleared on grounds of entrapment.)

These are famous stories. They’re why everyone knows it’s impossible to start a new car company in America. So Oliver isn’t going to try to do that. He doesn’t want to be a car company. Instead, he wants to license his technology and let someone else go through the hassle of actually making the cars. What he wants to sell is not a car but the intellectual property required to produce one. And he thinks this knowledge will be valuable because of the way US regulations are changing.

The previous year, in 2009, President Barack Obama struck a historic deal with the major automakers, creating, for the first time, a national tailpipe-emissions standard. By 2017, auto fleets will have to emit, on average, 213 grams of carbon dioxide per mile or less—a target a bit more lenient than the X Prize’s 200-grams-per-mile figure. Soon, Obama will drastically increase fuel economy standards as well, requiring all US fleets to average 54.5 MPG by 2025. The new rules boil down to this: If the automakers want to keep selling gas-guzzlers in years to come, they’ll also need to sell high-mileage cars. Maybe electric cars like the Chevy Volt and the Nissan Leaf will do the trick, but maybe not. What if the automakers can’t make electric cars fast enough, or can’t sell enough of them to raise the fleet average above the new regulatory bar? What if they decide they need some other kind of high-mileage ringer?

This is where Oliver comes in: He can help them do it faster. He can save them time. He can also save them money. An oft-quoted figure is that it takes $1 billion for an automaker to develop a new car “platform”—a basic architecture that can be adapted for different models. That money is for the retooling of the factory to make the car, plus the salaries of the people who work on it, the designers and engineers and executives and marketers and consultants, as well as for years of testing hand-built prototypes costing hundreds of thousands of dollars each. But Oliver is already making the prototypes. He has been exploring the abyss of lightness for three years now, mapping the wrong turns and expensive blind alleys, and he will continue to chart new territory this spring and summer, when he runs the Very Light Cars in the X Prize.

Not much is known about the physics of a very light car. A few foreign automakers, namely Volkswagen and Toyota, have built and tested ultra-lightweight prototypes in recent years, but their data are private, and they haven’t announced plans to bring those cars into production. No US automaker has publicly said it’s seriously investigating the approach. When a car gets very light, what happens in a side wind? What happens when a truck passes? “You don’t know,” Oliver says, “you really don’t know. You have to build a prototype and go test it. That costs millions of dollars.” Here in a small shop carved out of an old blue-jeans factory, Oliver is spending the money that the big companies aren’t willing to spend. “Anybody who decides today that they want to go build this, they have to start with a best guess,” he says. “And the best guess is only as good as their best engineer. And they may have a better best guess than our first best guess and they may have a worse best guess than our first best guess, but we’re past the best guess.”

It’s worth it for Oliver to spend the money, he says, because the payoff is potentially so huge. He thinks there’s room not only for a new kind of car but for a whole new line of cars. Just as there is a range of SUVs and compacts and hybrids, there will someday be a range of Very Light Cars, he says. Your “normal” cars—that’s the word he uses to describe every car now on the road—will weigh from 1,800 to 7,000 pounds. Your Very Light Cars will weigh from 600 pounds for a spartan model to 1,100 pounds for a decked-out six-seater. The normal cars will get 12 to 45 miles per gallon, and the Very Light Cars will get 70 to 130 miles per gallon. Oliver thinks the Very Light Car can cut a permanent notch in the market.

Which is optimistic of him, to say the least, but not absurd, not crazy, because certain cars have done this in the past. Starting in 2000, the Prius hybrid proved to reluctant automakers that there was a demand for green vehicles; today 4 percent of all cars sold in the US are hybrids. Four decades earlier, in 1959, the British Motor Company released the Mini, which freed up space for passengers by mounting the engine sideways; most of today’s small front-wheel-drive cars are shot through with the Mini’s DNA. It was invented by a Greek British designer named Alec Issigonis, who had once built his own lightweight race car by hand, which he called the Lightweight Special. (Later in his career, Issigonis griped about the bureaucracies at car companies: “A camel is a horse designed by committee.”)

And of course there was the original Volkswagen, which eventually became known as the Beetle. Oliver likes to talk about the Beetle. Designed in the 1930s by the German engineer Ferdinand Porsche (yes, that Porsche) as a car for the European masses, and later championed by Adolf Hitler, the Beetle was defiantly minimalist, with a squat shape and a small engine in the rear, not the front. According to Beetle historian Andrea Hiott, at the end of World War II, when Allied forces occupied the German town of Wolfsburg, where Beetles were made, the Allies decided to let the factory continue to operate, keeping the company alive.

By the late ’50s, Volkswagen was aggressively marketing the Beetle in America, encouraging alienated twenty- and thirtysomethings to “Think Small.” And it worked. Stylistically, the car was like nothing else on the road—a flagrant departure from the past. Yet Americans bought Beetles, in droves, because the car met a need: It was fun, it was cheap, it was well built, and it didn’t use much gas. Owners came to love the Beetle because it was weird-looking, not in spite of it, and as Beetles rode off dealer lots across the land, merging with the general traffic, a mere engineering solution turned into a cultural icon.

Oliver says he wants to build a “Volkswagen for the 21st century”: a car with less stuff for a world running out of stuff. A car for a warming, unequal world where the rich get richer and the rest of us scrape by. Cars are essentially priced by the pound. You’re paying for the raw materials, the steel and plastic. An 800-pound car might retail for $20,000, max, in America, and he can make an even more inexpensive model for India and China, he says. If you heard about a car that was safe, fun to drive, ran on gasoline, got 100 miles per gallon, and cost $20,000, wouldn’t you want one?

Over lunch at a local Thai restaurant, Oliver holds court, keeping the men of Edison2 entertained with tales of past business capers. He’s best known in Virginia as a real estate developer, not a carmaker. Oliver owns more than 50 properties in Charlottesville and Lynchburg. That’s how he makes his living—by collecting rent. But due to the recession, he says, “We’re not making money these days.”

Oliver makes real estate sound less like a career than a series of lucky accidents and sudden passions. “Part of my real estate empire is based on asbestos,” he says, putting air quotes around empire. “I bought the National Linen building. I removed the asbestos personally. It took me six months. That was one of my on-purpose real estate deals, ha ha ha.”

The guys from the shop are all here, 10 of them, including Ron Mathis, 50, the lead engineer, and Brad Jaeger, 24, an engineer and driver who’s raced Daytona prototypes in Grand-Am endurance road races.

“I tried to buy the USS United States,” Oliver says. He explains that the ship was an old decommissioned luxury liner rusting in a dock in Philadelphia. Years back, he got it in his head that he would tow the ship to New York, anchor it on a pier, and turn it into luxury apartments. “It’s a big building,” he says. “So that was my thinking. I’m a nut. Three hundred thousand square feet. I thought I could really do it. I would get someone big to come in, like Trump. At that point, you know, I would just be a 2 percent owner, but who cares?”

“What’s interesting,” says Brad, steering the conversation back toward the Very Light Car, “is that our car has about the same aerodynamic drag, or less, as a motorcycle.” Aerodynamic drag is a function of both the sleekness of a vehicle’s shape and the “frontal area,” the portion that meets the air. Even though the Very Light Car has more frontal area than a motorcycle, its shape is far sleeker—think of how a motorcycle rider sits upright, offending the air—which makes up for its size.

Oliver recoils in his seat. “Doesn’t the Very Light Car have less drag than a motorcycle?” he asks.

“The same,” says Brad.? “No, it’s less.” ?”Are you sure?” asks Brad. “In the tests I did—”? Oliver interrupts: “With a very high degree of certainty—I would put $100 on it—we have a lower aerodynamic drag than the motorcycle.”

“I can show you the numbers when we get back,” Brad tells him.

“I don’t want to see your numbers,” Oliver says, swiping his paw at the air, and all the men at the table burst into laughter. “You are too late for me.”

For the rest of the afternoon, back at the shop, Oliver keeps pitching me on the Edison2 vision. The stakes grow ever higher: One minute he’s discussing the price of copper, and then he moves on to windmills, and now he’s sharing his thoughts about what it means that so many people in China ride bicycles. The connecting thread seems perfectly visible to Oliver, if not to me. It’s as if he’s been thinking big thoughts for years with nowhere to put them, and now that a journalist is here, pointing a tape recorder at his chin, he wants to upload everything all at once.

“With honest information we can come up with solutions,” he tells me, cheeks flushed, picking up speed, “and what we would like most is to position ourselves as the people who have spent more hours thinking about this than anyone else on the planet, and I think we have that honor today and as such we want to position ourselves where someone else who recognizes the virtue of what we’re doing says: I want these guys on my side!”

Oliver pinballs from station to station, checking in with his mechanics. “What you are seeing here is a day when 15 different things have fallen into our lap,” he says. Legal paperwork has to go out in the mail, because Edison2 is trying to patent several aspects of its Very Light Car technology. There’s also a crucial X Prize deadline to hit. Nineteen days from now, Edison2 has to demonstrate that each of its cars has been driven at least 100 miles, or it can’t compete. The first on-track phase, Shakedown, begins next month. The odometers on three of Oliver’s cars currently register at zero.

Oliver approaches Peter “PK” Kaczmar, the British crew chief and lead mechanic. A little while ago, I heard him singing along with the radio. PK is busy putting brakes on one of the cars—a brake on each wheel, four brakes in all. Oliver figures that two brakes, not four, will suffice for racking up the 100 required miles. He wants to get the car driving more quickly, to be sure he’ll make the deadline. PK responds that he’d rather not cut that corner. He wants to do the brakes the proper way the first time so that he doesn’t have to redo them later. Oliver blurts out, “I don’t give a flying fuck how you do it. The reality is that it drives. The requirement is not that it drives well. It just has to drive.”

A young mechanic, Bobby Mouzayck, whose right biceps is inked with a skull that has exhaust coming out of its cheekbones and throttle parts for eyes, assures his boss they’ll get it done.

Oliver walks away, mumbling. “Sometimes you can get so paranoid about this shit,” he says. He plants himself in the center of the shop floor and announces, to no one in particular, that it doesn’t matter if there are only two brakes on the car, because “this car will stop on a shorter distance on two brakes than most cars will stop on four brakes.” He brightens. “This car is the dog in the room,” he says in his idiosyncratic English, meaning that it’s the alpha dog. He continues, “This car outperforms my Volkswagen Jetta in every way. It just does.”

When Oliver speaks, he tends to monologue, and now he launches into a long one. The topic is risk, which he talks about as if it scares and thrills him at the same time. He says his wife is sick of his long nights in the shop, away from their kids. He says he’s taking the biggest gamble of his life, and he hears about it every night when he goes home. He has already spent $2 million to develop the Very Light Car. The money has come from private investors and his own pocket.

“I have to say, I’m very reckless with this, financially,” Oliver says. “For a while, I didn’t have the funding lined up, but I was pushing ahead anyway, having faith that I would find the funding. And this is an all-or-nothing deal. You get nothing back if you design half a car. So it’s risky. And even if we win the X Prize, it’s not a given that people will give us money to take it further. From my point of view it’s truly a once-in-a-lifetime opportunity. It’s probably the most meaningful thing that I could do.”

Toward the end of the afternoon, seven elderly men arrive at the workshop—members of an alternative-vehicle club at a Lynchburg senior center. They’ve read about the Very Light Car in the local newspaper and want to see it in person. This kind of thing happens a lot. People walk in off the street.

Oliver greets the men warmly. He tells them they’re from “the best generation”—the last American generation to have invented great things. He says, “We feel we’ve discovered a whole new market segment of what a car could be.” He pulls out a lug nut. “Who wants to hear about the very light lug nut from the big nut himself? “

Then, after a few words about the virtues of lightness, Oliver plants himself next to the shiny nose cone of the silver car and glances, almost sleepily, off to the side—a bit of casual bravado. This prototype is completely functional. It seems to have all of a real car’s weight and heft: four wheels, seats, a steering column. Oliver stretches out his right hand. He makes a thumbs-up gesture. Ever so lightly, as the men watch spellbound, he touches the silver skin. He pushes the car across the floor with only his thumb.

Read our interview with author Jason Fagone.