<a href="http://www.shutterstock.com/pic-98237342/stock-photo-the-blue-plastic-barrels-for-storage-of-chemicals.html?src=bf28db30205b8cef92b2884a90c39169-1-47">Elena Larina </a>/Shutterstock

This story was originally published by the Center for Public Integrity.

For more than three decades, workers, most of them women, have complained of dreadful conditions in many of Windsor, Ontario’s plastic automotive parts factories: Pungent fumes and dust that caused nosebleeds, headaches, nausea, and dizziness. Blobs of smelly, smoldering plastic dumped directly onto the floor. “It was like hell,” says one woman who still works in the industry.

The women fretted, usually in private, about what seemed to be an excess of cancer and other diseases in the factories across the river from Detroit. “People were getting sick, but you never really thought about the plastic itself,” said Gina DeSantis, who has worked at a plant near Windsor for 25 years.

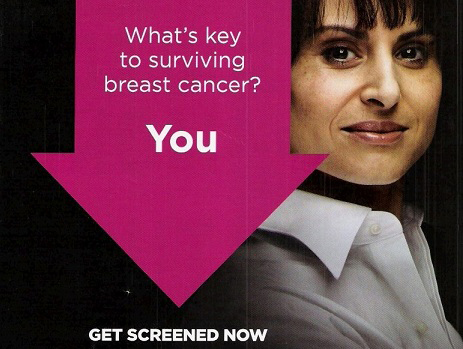

Now, workers like DeSantis are the focal point of a new study that appears to strengthen the tie between breast cancer and toxic exposures.

The six-year study, conducted by a team of researchers from Canada, the United States, and the United Kingdom, examined the occupational histories of 1,006 women from Ontario’s Essex and Kent counties who had the disease and 1,146 who didn’t. Adjustments were made for smoking, weight, alcohol use, and other lifestyle and reproductive factors.

The results, published online today in the journal Environmental Health, are striking: Women employed in the automotive plastics industry were almost five times as likely to develop breast cancer, prior to menopause, as women in the control group.

These workers may handle an array of carcinogenic and endocrine-disrupting chemicals. They include the hardening agent bisphenol A (BPA)—whose presence in polycarbonate water bottles and other products has unnerved some consumers—plus solvents, heavy metals and flame retardants.

Sandy Knight, who worked at two Windsor plastics plants from 1978 to 1998, had a breast cancer scare in 2000, when she was 41. The cancer was at Stage III—”invasive and fast-growing,” said Knight, 53, who now works at a Ford parts distribution center near Toronto. She had a single mastectomy and, following 10 years of hormonal treatment, is in remission.

Asked if she believed her disease was work-related, Knight said, “I’m suspicious of it because of all the exposures we had.” She remembers the “nauseating kind of odor,” the burning eyes and headaches, all the women with cancer, sterility, and miscarriages. She’s upset that little seems to have changed at some plants.

“Why am I speaking to people today, in 2012, who are doing the same processes I did in 1980?” Knight asked. “It just seems like we’re fighting the same battle. A lot of these chemicals should be removed from the workplace.”

The study population included women who had worked at more than 40 plastics factories in the Windsor area. But the implications are broader: Workers in similar plants around the world are exposed to many of the same chemicals. So are members of the public, who encounter the substances—albeit in lower doses—in the course of their daily lives.

“These workplace chemicals are now present in our air, water, food and consumer products,” said one of the two principal investigators, James Brophy, an adjunct faculty member at the University of Windsor and a former occupational health clinic director. “If we fail to take heed then we are doing so at our own peril.”

Jeanne Rizzo, president of the Breast Cancer Fund, a San Francisco-based group that has pressed for more research into environmental causes of a disease that claimed nearly 40,000 lives in the United States last year, called the Windsor study “a very powerful piece of work. The piece that’s really been missing for female breast cancer is occupation.”

In the United States, an estimated 150,000 female workers in the plastics and synthetic rubber industries are likely exposed to many of the same chemicals as the women in Windsor, including polyvinyl chloride, or PVC, plastic; acrylonitrile; formaldehyde; and styrene.

“I think the findings, although they’re clearly based on Canadian groups, go well beyond Canada,” said another of the Windsor study’s coauthors, Andrew Watterson, director of the Centre for Public Health and Population Health Research at the University of Stirling in Scotland. “They’re going to be significant for plastics workers in Europe, India, China, Africa, the United States. The chemicals will have the same toxic effects. The same diseases will develop.”

Even minuscule amounts of endocrine-disrupting chemicals like BPA can be worrisome, Watterson said. “This research is raising big questions both about what the [workplace] standards are and even about what happens if conditions are very good, with low-level exposures,” he said.

In a written statement, a spokeswoman for the US Occupational Safety and Health Administration, said, “We look forward to reading this paper…and plan to explore how we may use the findings in protecting workers from hazardous exposures.”

The American Chemistry Council, the main chemical industry trade association in the United States, questioned the study’s conclusions, saying it includes “no actual determination of [worker] exposures.” The study’s estimates of risk seem to be based on a small sample and are “statistically very uncertain,” the council said in its statement.

“The well-established risk factors for breast cancer are not chemical exposures, but rather a combination of lifestyle and genetic factors,” the council wrote.

Barry Eisenberg, a spokesman for another US trade group, the Society of the Plastics Industry, declined to comment on the study, saying, “We don’t have the expertise.” Eisenberg declined to answer general questions about worker and consumer health, although his group has had an Occupational Health and Environmental Issues Committee since 1985.

The Canadian Plastics Industry Association did not respond to requests for comment. The president of the Canadian Automotive Parts Manufacturers’ Association declined to comment.

Life in the Factories

Modern cars and trucks are loaded with plastics: bumpers, door panels, license-plate brackets. Dozens of factories in and around Windsor make these parts from plastic pellets melted and shaped in injection molding machines. The parts are then shipped to auto manufacturers.

The Big Three US automakers expressed varying degrees of concern about conditions in the parts plants.

General Motors said its suppliers are “independent businesses which must meet the Health and Safety legislation in the jurisdictions in which they operate.” Ford said it “requires suppliers to ensure that our products—no matter where they are made—are manufactured under conditions that demonstrate respect for the people who make them.” And Chrysler said that while its suppliers are “responsible for their own legal compliance,” its policies “restrict us from using suppliers who we learn do not comply with our requirements or environmental and health and safety laws.”

Conditions in some of the Windsor plants have improved, workers say. In years past, for example, hot plastic would be removed from the molding machines and dumped on the floor, where it might lie for up to an hour. Some companies have altered this process, known as purging, requiring that the reeking muck be put into covered barrels.

Others have relocated grinding machines—bladed devices that chew up scrap plastic and spit out huge quantities of dust—to isolated areas to reduce worker exposures.

Workers say, however, that a lack of local ventilation—vacuums that can suck up fumes and dust straight from the molding and grinding machines and direct them outside—is still the norm at many facilities.

The machines disgorge “pretty toxic stuff—either carcinogenic or endocrine-disrupting chemicals,” said Robert DeMatteo, a retired health and safety director for the Ontario Public Service Employees Union and lead author of an article on the plastics industry scheduled for publication early next year in the journal New Solutions. “All you’re going to do with general ventilation is just dilute it.”

Carol Bristow got into the industry in 1989, having grown impatient with a dead-end cashier’s job at the A&P. “I never felt working in a factory would be my calling,” Bristow said. “The first six months I would come home in tears and in pain, almost praying to God that I wouldn’t get my seniority because it seemed like the wrong place to be. But the money kept coming in, and you just adjusted.”

In 1992, when she was 34, Bristow was diagnosed with cancer in her right breast, which was removed along with about 20 lymph nodes. She kept working and developed endometriosis, a painful condition in which cells from the lining of the uterus grow outside the uterine cavity. Some studies have linked endometriosis with exposure to chemicals such as dioxin, a byproduct of PVC incineration and chlorine production. Bristow underwent a hysterectomy in 2001.

As all of this was going on, Bristow was being tormented by bladder infections. Benign tumors were removed from her bladder in 2010 and again in August of this year. “I’ll have to be scoped every three months for the rest of my life,” she said, referring to a procedure called cystoscopy, in which a tube-like viewing device is inserted through the urethra into the bladder. One study found that women who had worked in the plastics industry had a more than threefold risk of developing bladder cancer.

Why does Bristow stay?

The pay, she explained, is a respectable $22 an hour, with benefits, in a tough economy. “Who’s going to hire me?” she asked.

The owner of Bristow’s factory, which bought the facility in 2001, says it is unaware of any worker health concerns and has a “consistently strong track record—recognized by workers and regulators – of protecting its employees’ health and safety.”

“Horrifying” Symptoms

James Brophy and his partner, Margaret Keith, both Ph.D.s with backgrounds in occupational health, began studying Ontario plastics workers in the late 1970s.

“It wasn’t something we chose to be interested in,” Keith said. “We had people come to us”—notably, a union official from a Windsor plant concerned about what seemed to be an abundance of disease among female workers.

Keith, Brophy, and a physician put together a health questionnaire, which was circulated at five plants. Reports of nosebleeds, headaches, and nausea came back. Some operators said the fumes had made them pass out at their machines. “The level of symptoms was pretty horrifying,” Brophy said.

In 1981, the CBC broadcast a documentary, Dying for Work, which highlighted conditions in the Windsor plants. “We thought that would really start the ball rolling” toward better ventilation and other improvements, Keith said. “Absolutely nothing happened.”

Keith and Brophy lost contact with the plastics workers for more than a decade, until several turned up at their occupational health clinic in 1993 to report that they had had miscarriages or difficulty conceiving. Keith, Brophy and clinic staff developed a second questionnaire for circulation in the plants. “We found a lot of acute symptoms as well as reproductive problems and some cancers,” Keith said.

Around the same time, Keith and Brophy convinced officials at the Windsor Regional Cancer Center to begin collecting work histories of cancer patients. This led to an initial study, completed in 1999, which found an increased risk of breast cancer among women who farmed. A subsequent study, finished in 2002, looked at the work histories of 564 women with breast cancer and 599 who didn’t have the disease. Again, a strong association between farming and breast cancer was noted; an even stronger link was found among women who’d farmed and then gone to work in the auto industry.

The new study, funded by groups including the Canadian Breast Cancer Foundation-Ontario Region, examined a population twice as large and featured a more detailed questionnaire. Workers in the plastics industry, it found, are exposed to a brew of carcinogenic and estrogenic chemicals, also known as endocrine disruptors, which interfere with the hormone system and can cause tumors, birth defects, and developmental disorders. This complex mixture, Brophy said, may be more dangerous than any one compound.

The study found that, in addition to the plastic workers, women who worked in food canning and agriculture and at bars, casinos, and racetracks had elevated breast cancer risks. The highest risk for pre-menopausal women—nearly six times that of the controls—was found in canning, an industry in which workers may be exposed to BPA in epoxy can linings and pesticides released from food during cooking.

The primary risk factor associated with agriculture is pesticide exposure, the study found. Women who work at bars, casinos, and racetracks are exposed to tobacco smoke, it noted, and also subjected to “disruption of circadian rhythms and decreased melatonin production resulting from night work,” which other research has shown to be associated with breast cancer.

In general, breast cancer is an older woman’s disease; a 60-year-old has a greater chance of developing the disease than does a 30-year-old. Many of the victims in the Windsor plastics factories are in their 30s, 40s and 50s, say six current and former workers, from multiple plants, interviewed by the Center for Public Integrity.

“We’re sitting here after three decades, and you see the weight of the evidence that these substances pose serious health problems, yet there’s nary a mention of the risk that blue-collar workers bear, particularly women,” Brophy said. “They’re just not on the radar. Had we paid more attention to them, the harm these substances cause would have been seen much sooner and we might have prevented them from becoming so ubiquitous in the environment.”

The President’s Cancer Panel, an advisory committee in the United States attached to the National Cancer Institute, reported in 2010 that “the true burden of environmentally induced cancer has been grossly underestimated.” The panel singled out BPA as one of the chemicals that may be causing “grievous harm.”

The research in Windsor buttresses other recent work on breast cancer and chemicals. A French study in 2011, for example, found elevated risks among women who worked in plastics, rubber and textile manufacturing. A study from Mexico in 2010 found that the presence of metabolites of phthalates—softening agents for plastics that have endocrine-disrupting properties—in urine was “positively associated” with the disease. A 2007 paper from US researchers identified 216 chemicals that had been associated with mammary gland tumors in animals.

The lone American coauthor of the Windsor study, Robert Park of the National Institute for Occupational Safety and Health, said he was “surprised by how strong the findings were. There was a lot of confirmation of prior concerns, which is always the goal but not always achieved by these kinds of studies.”

“Race to the Bottom”

The Canadian plastics workers say they have little faith in their country’s system of workplace regulation. Factory inspections are haphazard, they say, and chemical standards in many cases are weak, meaning few overexposures—by the legal definition, anyway—are cited. Conditions improve incrementally, if at all.

“It’s a race to the bottom,” said Sari Sairanen, national health and safety director for the Canadian Auto Workers union, which represents about 4,000 workers in parts plants, some of which make plastics. “For the worker, there’s the fear of losing your job or the fear of retribution from your employer if issues are raised.”

Bristow, a union member, said that many workers seem unwilling to confront their bosses with health questions. Too often, she said, a woman disappears from the factory floor and her coworkers don’t learn until much later that another case of breast cancer has been diagnosed.

The Ontario Ministry of Labor is committed to the prevention of work-related diseases, a spokesman said in a statement. The ministry uses a multifaceted approach that includes health and safety inspection “blitzes” and the updating of exposure limits, the spokesman wrote. “We make decisions on the latest science and we welcome any report that will bring a better understanding of occupational exposures to ensure that workers are protected from unsafe exposure levels.”

There is also deep dissatisfaction with workplace regulation in the United States. Adam Finkel, former director of health standards programs for OSHA, said the vast majority of exposure limits enforced by the agency in American workplaces are based on scientific data from the 1960s or earlier, even though an estimated 150 workers die each day of work-related diseases.

Limits for only 16 substances have been updated, a consequence of industry challenges and hesitancy on OSHA’s part. There are no limits for BPA. The limits that do exist for chemicals used in plastics—say, vinyl chloride, an ingredient in PVC—were designed to address cancer and acute symptoms, not the sort of hormonal damage that can occur when women of childbearing age receive low-level exposures. Only 18 percent of OSHA inspections last year focused on potential health, as opposed to safety, hazards.

“It’s a terrible record, and I’m getting more pessimistic as the years go by,” said Finkel, who runs the Penn Program on Regulation, a research center at the University of Pennsylvania Law School.

In its statement, OSHA acknowledged, “Many of our current Permissible Exposure Limits are out of date and inadequately protective, and we do not have limits for many other chemicals. OSHA is currently examining ways to strengthen our efforts related to workplace chemical exposures, as well as ways to respond to the identification of new, emerging hazards.”

The US Environmental Protection Agency’s record on chemicals—like OSHA’s—is thin.

Chemicals found in the workplace—among them BPA and phthalates—also may pose health risks to the general public. Of the more than 80,000 chemicals registered for use today, however, the EPA has required only about 2 percent to undergo even basic testing. At the root of the problem is the Toxic Substances Control Act of 1976, which puts the onus on the EPA to prove that a chemical is harmful before it can be banned or its use restricted. This burden is almost insurmountably high; the EPA has banned narrow uses of only five chemicals since the law was passed.

The Obama EPA has begun to disallow claims of “confidential business information” that for decades enabled companies to conceal the identities of chemicals when they submitted health and safety data, even if significant risks had been flagged.

Industry, however, is fighting an attempt by the EPA to extend its anti-secrecy policy to new chemicals; a proposed rule has been under review by the White House Office of Management and Budget for nearly a year.

A proposal to add BPA, phthalates and a certain class of flame retardants to an EPA “chemicals of concern” list has been at the OMB for more than 900 days. The EPA says that these chemicals “may present an unreasonable risk to human health and/or the environment” and wants to use its authority under the law to list them, a step that would, among other things, require producers to notify the EPA when they exported the chemicals, and the EPA to notify the recipient governments.

Industry groups such as the US Chamber of Commerce oppose the action, saying it amounts to an unwarranted blacklisting.

An EPA spokesman did not respond to requests for comment. An OMB spokesman declined to comment.

The US Food and Drug Administration no longer allows the use of BPA in baby bottles or infant-training cups. The FDA acted, however, only after receiving a petition from the American Chemistry Council, which said that manufacturers of these products had already abandoned the chemical to meet consumer preference. “The agency continues to support the safety of BPA for use in products that hold food,” an FDA spokeswoman said in a written statement.

The Canadian government didn’t wait for an industry petition. It banned BPA in baby bottles two years ago, based on concerns about the chemical’s toxicity.

Brophy, one of the researchers in Windsor, approves of the ban. But he worries about the women in the plastics plants, who soak up BPA and other chemicals on the job.

“There seems to be widespread concern about consumer exposures but almost no concern for the most highly exposed population—the blue-collar workers,” he said. “These women remain invisible and their cancer risk largely ignored.”

The Center for Public Integrity is a nonprofit, independent investigative news outlet in Washington, DC. For more of its stories go to publicintegrity.org.