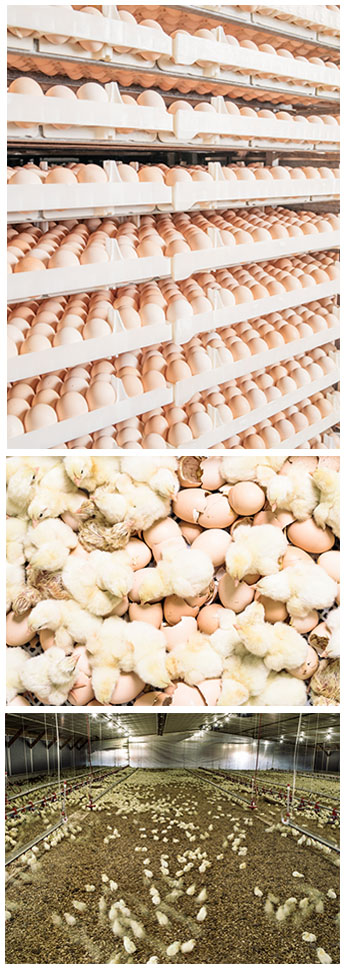

The massive metal double doors open and I’m hit with a whoosh of warm air. Inside the hatchery, enormous racks are stacked floor to ceiling with brown eggs. The racks shake every few seconds, jostling the eggs to simulate the conditions created by a hen hovering atop a nest. I can hear the distant sound of chirping, and Bruce Stewart-Brown, Perdue’s vice president for food safety, leads me down a hall to another room. Here, the sound is deafening. Racks are roiling with thousands of adorable yellow chicks looking stunned amid the cracked ruins of their shells. Workers drop the babies into plastic pallets that go onto conveyor belts, where they are inspected for signs of deformity or sickness. The few culls are euthanized, and the birds left in each pallet are plopped on something like a flat colander and gently shaken, forcing their remaining shell debris to fall into a bin below. Now clean and fluffy, the chicks are ready to be stacked into trucks for delivery to nearby farms, where they’ll be raised into America’s favorite meat.

Not long ago, this whole protein assembly line might have been derailed if each egg hadn’t been treated with gentamicin, an antibiotic the World Health Organization lists as “essential” to any health care system, crucial for treating serious human infections like pneumonia, neonatal meningitis, and gangrene. But the eggs at Perdue’s Delmarva chicken production farms have never been touched by the drug.

That’s extremely uncommon in corporate factory farming. Currently, livestock operations burn through about 70 percent of the “medically important” antibiotics used in the nation—the ones people need when an infection strikes. Microbes that have evolved to withstand antibiotics now sicken 2 million Americans each year and kill 23,000 others—more than homicide. Even though public health authorities from the Food and Drug Administration and the Centers for Disease Control and Prevention have long pointed to the meat industry’s reliance on antibiotics as a major culprit in human resistance to the drugs, the FDA has never reined in their use.

I’m in Delmarva, the peninsula composed of pieces of Maryland, Virginia, and Delaware, because it is Big Chicken country—the teeming barns that dot its rural roads churn out nearly 11 million birds per week, almost 7 percent of the nation’s poultry. And Perdue, the peninsula’s dominant chicken company and the country’s fourth-largest poultry producer, has set out to show that the meat can be profitably mass-produced without drugs. In 2014, the company eliminated gentamicin from all its hatcheries, the latest stage of a quiet effort started back in 2002 to cut the routine use of antibiotics from nearly its entire production process. (Read about the disturbing new report by OxFam on contract chicken farming here.)

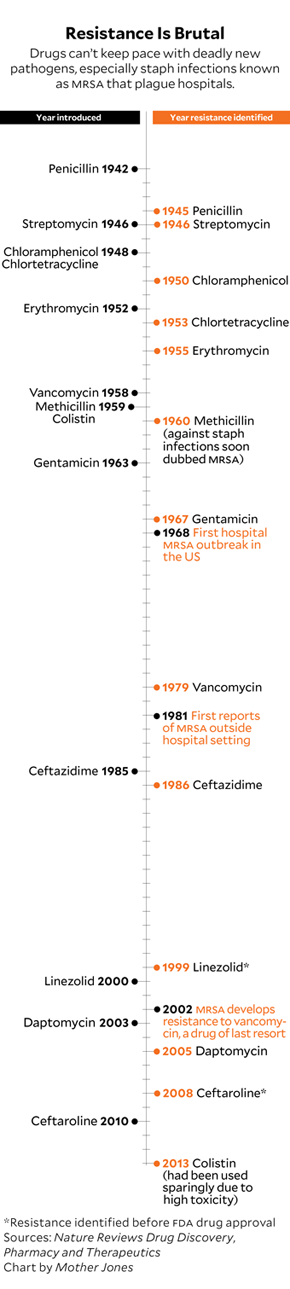

In 1928, Scottish biologist Alexander Fleming discovered a mold-based compound dubbed penicillin that could kill common microbes that cause dangerous infections. But even as they began to revolutionize medicine, antibiotics had a fundamental flaw. While collecting the 1945 Nobel Prize in medicine, Fleming warned that it’s “not difficult to make microbes resistant to penicillin in the laboratory by exposing them to concentrations not sufficient to kill them.”

When an antibiotic attacks a colony of bacteria, the great bulk of the bacteria dies or can no longer reproduce, and the infection is cured. But a few rogue microbes can withstand the assault and pass their hardy genes on to their progeny. If you unleash the same antibiotic on the same bacteria over a long enough time, you’ll create a bacterial strain that can thumb its nose at the drug. And it isn’t just turbocharged Darwinism that makes our antibiotics so vulnerable. Through a process called “conjugation,” genes—including ones that have become resistant to particular antibiotics—can bounce from one microbe to another.

Though we’ve known this for more than 70 years, doctors have too often treated antibiotics as a sturdy crutch, not a delicate tool to be used sparingly. The CDC estimates up to half of all antibiotics used in US medicine are improperly prescribed, speeding up resistance. But that is nothing compared with how recklessly they’ve been used in factory farms. When you treat thousands of chickens in a huge enclosed barn with, say, steady doses of tetracycline, you risk generating an E. coli bug that can resist the antibiotic you threw at it, and that bug’s new superpowers can also jump to a strain of salmonella that happens to be hanging around. Now, two nasty pathogens that plague humans have developed tetracycline-resistant strains.

And the worst part is that antibiotic use in factory farms isn’t mostly a matter of keeping animals healthy. In 1950, a pharmaceutical company called American Cyanamid—now part of Pfizer—wanted to see if giving chickens vitamin B-12 made them fatter, so it ran some experiments. The idea seemed to work. But the researchers soon discovered it wasn’t the vitamin that had fattened the birds; it was traces of an antibiotic called aureomycin. (B-12 can be a byproduct of aureomycin production; the vitamin researchers used had come from making the antibiotic.)

This discovery revolutionized meat production. Adding a dash of antibiotics to feed and water rations magically made birds, pigs, and cows grow plumper, saving on feed costs and slashing the time it took to get animals to slaughter. In 1977, the General Accounting Office reported that “the use of antibiotics in animal feeds increased approximately sixfold” between 1960 and 1970. “Almost 100 percent of the chickens and turkeys, about 90 percent of the swine and veal calves, and about 60 percent of the cattle raised in the United States during 1970 received antibiotics in their feed.”

In turn, antibiotics helped launch the rapid industrialization of chicken production. In 1950, at the dawn of the antibiotic revolution, 1.6 million US farms were raising about 560 million birds. By 1978, only 31,000 mostly large chicken farms remained, and they were cranking out more than 3 billion birds.

Meanwhile, a steady accumulation of scientific research revealed a mounting public health crisis. At the end of the ’60s, a scientific committee in the United Kingdom found that using antibiotics in animal feed produced large numbers of resistant bacteria that could be transmitted to people. Similar findings were reported by an FDA task force in 1972, and as a result, the agency issued regulations requiring drug manufacturers to prove their agricultural products didn’t contribute to resistance. If they couldn’t, their approval to sell the drugs would be revoked.

So the Animal Health Institute, a trade group of animal-pharmaceutical manufacturers, contacted Stuart Levy, a young Tufts University researcher who specialized in antibiotic resistance. The group wanted Levy to feed tiny, daily doses of antibiotics to chickens and see if the bacteria in their guts developed resistance. The drug companies were convinced the results would “get the FDA off their backs,” says Levy.

Levy found a family farm near Boston and experimented on two flocks of chickens. One got feed with small amounts of tetracycline. The other went drug-free.

Within 48 hours, strains of E. coli that were resistant to tetracycline started to show up in the manure of the birds fed drugs. Within a week, nearly all the E. coli in those birds’ manure could resist tetracycline. Within three months, the E. coli showed resistance to four additional antibiotics the birds had never been exposed to: sulfonamides, ampicillin, streptomycin, and carbenicillin. Most striking of all, researchers found that E. coli resistant to multiple antibiotics was appearing in the feces of the farmers’ family members—yet not in a control group of neighbors.

The results, published in the New England Journal of Medicine, were so stunningly clear that Levy thought they would prompt the industry to rethink its profligate antibiotic use, or at least inspire the FDA to rein it in. But the industry rebuffed the study it had bankrolled, questioning the validity of the data, Levy says. In 1977, the FDA proposed new rules that would have effectively banned tetracycline and penicillin from animal feed, but the House agriculture appropriations subcommittee, led by agribusiness champion Rep. Jamie Whitten (D-Miss.), ordered the FDA to wait, “pending the outcome of further research.”

Those proposed 1977 bans remained in limbo for decades, dormant but officially “under consideration”—until 2011, when the FDA finally ditched them and let companies take a voluntary approach to curtailing antibiotic use. Meat producers were given until the end of 2016 to wean themselves from antibiotics. At that point, the agency warned, it would consider banning certain antibiotics if its light-handed approach did not “yield satisfactory results.” However, the plan also gave industry a gaping loophole: While it suggested livestock producers should no longer use human-relevant antibiotics as growth promoters, it left companies free to use them to prevent disease.

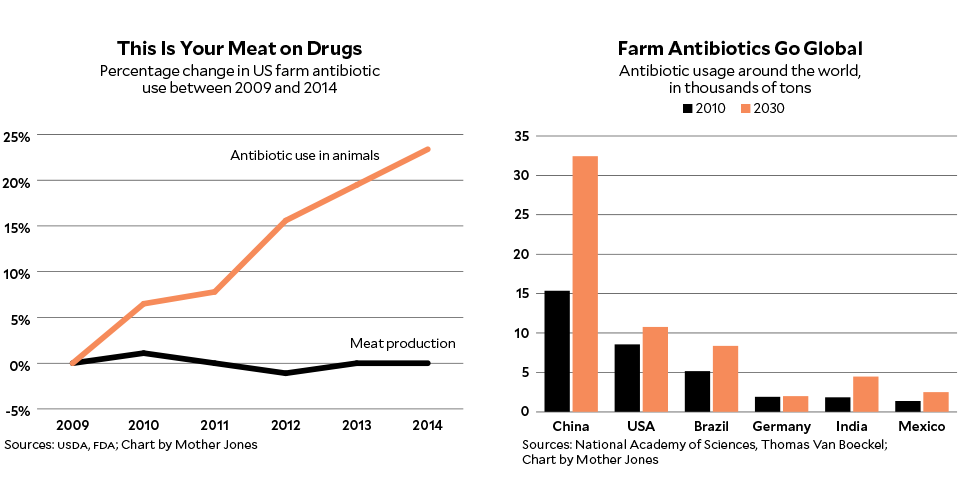

Unsurprisingly, the industry’s appetite for antibiotics has remained voracious. According to the FDA’s latest figures, antibiotic use on US farms surged 23 percent between 2009 and 2014, even as overall US meat production leveled off. In 2014, livestock operations used 20 million pounds of antibiotics important to humans—while doctors used about 7 million pounds.

A few years ago, I came across a Consumer Reports study of bacteria on supermarket chicken. The magazine had found that Perdue chicken was far less likely to carry bacteria resistant to more than one antibiotic than chicken from other producers, including Tyson and Foster Farms. Consumer Reports said Perdue’s good showing marked the “first time since we began testing chicken that one major brand has fared significantly better than others across the board.” When I asked Urvashi Rangan, a Consumer Reports researcher, why Perdue had done so well, she credited the company’s policy against using growth-promoting antibiotics.

As a longtime critic of industrial agriculture, I was surprised to learn Perdue had such a policy. I knew it was a leading supplier of chicken labeled “no antibiotics ever,” but this study showed that even its conventional chicken was far less likely to carry resistant bacteria than such chicken from other producers. Could it be that this one company was tacking against industry norms and taking the science seriously?

Historically, most birds bound for market not only got antibiotics in their feed, but were dosed with drugs before they even hatched. Bruce Stewart-Brown, who is 59 years old and trim, explains why as we walk through the hatchery. About 40 years ago, a herpes virus called Marek’s disease began to attack chickens, and vets discovered that vaccinating the chicks while they were still in their shells could inoculate them for life. But when you penetrate eggs with a needle loaded with the vaccine, the tiny hole you create opens a door, welcoming bacteria in. To solve this problem, hatcheries added small amounts of gentamicin to the vaccine to prevent bacteria from getting a foothold in the bird.

This method was so efficient that, decades later, the hatchery ended up being the trickiest place for Perdue to remove antibiotics from production. The company gets its eggs from contract breeders, and in the past eggs often arrived covered in bacteria-laden manure. Now Perdue requires its breeders to deliver clean eggs. Perdue also used to mix its Marek’s vaccines in the middle of a less-than-pristine hatchery. Today the company mixes the drugs under sterile laboratory conditions and injects clean, antibiotic-free vaccines into clean eggs. It took a while, but by March 2014 the company had banished antibiotics from all 16 of its hatcheries.

Stewart-Brown and I leave the hatchery and head to one of the company’s contract farms, where chicks are fattened for slaughter. As we drive through rolling corn and soybean fields, we have a surprisingly blunt conversation. “We already know that we create resistance with the products we use, and we’ve known that for years,” he says. Perdue hasn’t studied whether these resistant bacteria leave the farm and endanger the public, either via workers or the chicken sold to consumers. Then he says something remarkable for an agribusiness exec: “We know there’s likely some sort of transition.”

He’s right. The results of Stuart Levy’s 1976 study—showing that farmers who come into contact with antibiotic-treated birds quickly pick up drug-resistant bacteria—have been corroborated several times. In a 2013 FDA study of chicken bought nationwide, 60 percent of the salmonella that was detected could resist at least one antibiotic, meaning consumers are one unclean cutting board or unwashed hand away from a nasty bug. Antibiotic-resistant bacteria have also been found in chicken manure, on vegetables grown in fields fertilized with it, and even, according to a 2008 Johns Hopkins study, on the interior surfaces of cars that drive behind trucks hauling chickens to slaughter.

After 20 minutes, we pull into a driveway toward two long chicken houses, 40 feet wide and stretching 500 feet back. As with most US chicken facilities, these are run by a quasi-independent farmer who is paid to raise the birds using company-supplied chicks and feed under Perdue’s tightly controlled conditions. (Read about Perdue’s recent turnaround on a controversial contract stipulation here.) The fee this farmer earns is calculated through a competition with his peers—the farmers who deliver the heaviest and healthiest birds from a given amount of feed are rewarded with higher pay.

In other words, historically the incentive to use antibiotics was built in. We get out of Stewart-Brown’s truck and he leads me to a silo that stores the food Perdue has delivered for this flock. He grabs a laminated “feed ticket” that lists exactly what’s inside: protein, fiber, fat, and one additive, narasin.

Narasin is in a class of antibiotics called ionophores, which aren’t used in human medicine and are the only antibiotics remaining in Perdue’s feed, Stewart-Brown says. “Twelve years ago if you picked this up, it would have said narasin and one or two others,” he adds—drugs that might have also been prescribed to people.

About a third of the company’s flocks still get ionophores because of a specter that haunts chicken production everywhere: coccidiosis, a parasitic intestinal condition that can trigger severe digestive trouble and cause chickens to stop growing. The industry has relied on ionophores to control coccidiosis for decades. While most researchers I’ve spoken to don’t see ionophores as a major health threat, there is evidence bacteria that evolve to withstand them can also resist an antibiotic used by people, bacitracin. So Perdue is phasing out ionophores in favor of a vaccine for coccidiosis.

Other than the remaining ionophores, Perdue only uses antibiotics to treat a sick flock—typically about 4 percent of its birds each year. As of early 2016, two-thirds of the 676 million birds Perdue slaughters every year never get a drop of antibiotics in their entire lives, not even narasin.

Stepping into the 20,000-square-foot barn with its 40,000 chickens, I brace for an unbearable stench. Instead, I get a mild barnyard manure smell and a much stronger, toasty, sweet aroma of chicken feed—a mix of corn and soybeans that I remember from my own days tending a small outdoor flock. There is no stench, I realize, because the chicken house is well ventilated and clean, with plenty of straw on the floor to absorb manure. The room is divided lengthwise by several long, slender feeders full of the corn and soybean mix, and by low pipes from which hang metal water nipples every few inches. I move into the massive structure and thousands of birds serenade me with a steady din of clucks; as I walk by, they part as if I’m Moses in a feathery sea.

There amid an ankle-high vortex of fowl, I wonder: If these chickens aren’t eating antibiotics to spur weight gain, how do they get plump enough to ensure Perdue’s profits and some money for its farmers?

Stewart-Brown surprises me with his answers. The first is the opposite of antibiotics: probiotics, or live cultures (think of the acidophilus in yogurt) that can increase the good microbes in the gut, crowding out the bad ones. Probiotics boost the chickens’ immunity and even their growth rates, Stewart-Brown says. “Industry guys like to make fun of probiotics—I was one of them, five or six years ago,” he says. Back then, he adds, some probiotics marketed for use in chickens were “foo-foo dust,” but Perdue found that some actually work. For proprietary reasons, he won’t tell me which ones, but he explains that they seem to work by shifting the composition of the microbiome—the trillions of microorganisms that live in the guts of chickens and humans alike. (Emerging research suggests the microbiome influences everything from our immune systems to how we metabolize food, which is why antibiotics might be linked to the obesity epidemic.)

After Perdue bought an organic-chicken company called Coleman Natural Foods in 2011, it adopted another unorthodox therapy: oregano. The fragrant herb not only goes well with chicken; it also has antimicrobial properties that, when added to feed, help the birds stave off infections. But, I ask Stewart-Brown, won’t bad microbes develop resistance to oregano, too? Likely yes, he says, so Perdue only uses oregano to prevent particular infections, not as a constant additive.

Moving away from antibiotics, Stewart- Brown says, has forced him to think about the birds’ overall well-being—not traditionally a key concern in an industry that profits by converting feed into meat as cheaply as possible. Buying Coleman, he says, “woke up the bird side of us. We’d sort of shut that part down.” Now his staff asks questions that sound ripped from Portlandia: “Do the birds get what they want?” “Are they healthy?”

Perdue even turns off the lights in the chicken houses for four hours a night so the birds can rest. In the past, lights were left on 24 hours per day on the theory that chickens kept awake eat more and thus get fatter faster. Reducing stress by letting the birds rest, Stewart-Brown says, makes them healthier—and since healthy birds grow faster, the extra sleep has the same effect as constant feeding.

At this point I can’t help wondering why Perdue would go way beyond federal recommendations and leapfrog its competitors by switching from dangerous feed additives to finding its “bird side” with oregano and gentler lighting schemes.

Turns out I’m not the only one asking. Dr. Bob Lawrence, the director of the Center for a Livable Future at Johns Hopkins, which has generated reams of research on the dangers of routine antibiotic use on farms, ran into ceo Jim Perdue at a conference recently. Lawrence asked Perdue what had driven the company’s flight from antibiotics. “I was hoping he would say, ‘The research coming out of your center,'” Lawrence says. Instead, Perdue credited worried consumers.

Stewart-Brown says he and his colleagues saw an increase in queries about antibiotics from consumers starting in 2002—perhaps not coincidentally a year after the publication of Fast Food Nation, Eric Schlosser’s bestseller about the dark side of the US food system. Far more than its competitors, Perdue has a history of courting consumers directly. For decades, while rivals sold essentially unbranded chicken to supermarkets, Frank Perdue peppered consumers with quirky TV ads featuring himself—a balding, skinny pitchman who repeatedly set the quality of his chicken apart from his competitors’. His tagline: “It takes a tough man to make a tender chicken.” The ads gave the company a human face, Stewart-Brown says, making people feel invested. Perdue learned to take its customers’ concerns seriously: “You can drown them with science to suggest they shouldn’t be worried, but the worry is real.”

He adds, though, that Perdue executives “could feel” federal regulatory changes coming and wanted to be prepared. In 1996, the FDA had started monitoring levels of antibiotic-resistant bacteria on retail meat, finding it in abundance. Five years later, right around when consumers started complaining, the agency came out with a vague set of recommendations for poultry veterinarians that called for “judicious” use of antibiotics. Those recommendations suggested a regulatory reckoning might be in the offing.

In 2002, Stewart-Brown published a paper in a small academic journal describing a massive experiment that he and two Perdue colleagues had started in 1998. Their research involved nearly 7 million birds raised over three years in 19 farms in North Carolina and Delmarva. The team took away growth-promoting antibiotics from half the chicken houses in both locations and then compared those birds’ weight gain and life spans with those of chickens kept on antibiotic-laced feed.

The differences in weight gain between the two sets of birds were tiny: In Delmarva, the antibiotic-free birds weighed on average just 0.03 pounds lighter than their peers; in North Carolina, they were just 0.04 pounds lighter—not much for chickens that end up weighing in at about five to six pounds.

I ask Stewart-Brown if the study was the impetus for Perdue going antibiotic-free systemwide. He says the results were key in demonstrating that you could get rid of the drugs without destroying profitability. When consumer demand for antibiotic-free birds started ratcheting up around the same time, he says, the company felt “confident” it could make the shift.

That confidence looks justified now, as accumulating evidence shows the growth-promoting power of antibiotics has been declining for decades. A 2015 Organisation for Economic Co-operation and Development review found that antibiotics sped up growth by up to 15 percent before the 1980s but only by about 1 percent after 2000—a change likely due to better nutrition, hygiene, and breeding. Perdue may simply have calculated that the benefits of using antibiotics for growth were too small, especially in the face of consumer demand and potential regulatory pressure.

Christopher Leonard, a former Associated Press agribusiness reporter who has written a book about the poultry industry, says Perdue was looking for ways to differentiate itself from bigger rivals: “They’re just trying to capture market share.” Joe Sanderson, the ceo of one of Perdue’s rivals, Mississippi-based Sanderson Farms, agrees. His company slaughters 7 percent of the chicken eaten in the United States, making it about the same size as Perdue. “Frankly, these people are doing it for marketing purposes,” he tells me. Sanderson, by contrast, has held to the old-school party line, maintaining that “there is no evidence that using these antibiotics for chickens leads to resistant bacteria.” Cost is the No. 1 decision maker when people go to the grocery store to buy chicken, he says, and using antibiotics remains the cheapest way to produce a lot of meat fast. “We believe the majority of chicken sold in grocery stores will continue to be grown with antibiotics,” he says.

Perdue sees a very different future. After 14 years, Stewart-Brown tells me that the company can now produce meat without antibiotics as fast and efficiently as it once did with them. Today, Perdue ships two kinds of chicken: About two-thirds of the company’s product is already labeled “no antibiotics ever.” It sells for about 20 percent more than the remaining third still treated with antibiotics. Overall, Stewart-Brown explains, Perdue spends an extra $3 to $4 for every $1 it saves in antibiotics reduction—but recoups those costs by charging shoppers a premium for that meat. Last year, the company’s sales grew faster than those of its competitors—even when the overall market declined.

What’s more, Perdue got ahead of the curve, according to Brett Hundley, a vice president and research analyst at BB&T Capital Markets. In recent years, as US sales at fast-food restaurants have stagnated, Chick-fil-A (2014), Subway (2015), and McDonald’s (2015) have all vowed to stop serving chicken treated with antibiotics that might also be used for humans. Last year, California passed a law that bans the use of antibiotics to promote growth and dramatically tightens the loophole for “prevention” of disease that was left open by the FDA’s 2011 guidelines. (Across the Atlantic, a European Union ban on growth-promoting antibiotics took effect in 2006.)

The rest of the chicken-producing giants (save for Sanderson) are scrambling to catch up. Not long after McDonald’s announced it would go antibiotic-free, Tyson, the nation’s largest chicken supplier, declared it would rid its flocks of all human-important antibiotics by September 2017. Sasha Stashwick, a policy analyst at the Natural Resources Defense Council, says this announcement marked a “tipping point for getting the chicken industry off antibiotics.”

Will the changes to Big Chicken ripple through the rest of the meat industry? The FDA doesn’t break down data about antibiotic use by species, but given that it grew 23 percent between 2009 and 2014, even as poultry producers began to dial back, it seems pork and beef producers were ratcheting up.

Hundley says antibiotic-free beef and pork command a hefty premium of between 30 and 50 percent. Even so, few producers are taking advantage of that incentive. To go fully antibiotic-free would take time because, he explains, a chicken’s short life cycle—about a month from when they are born to slaughter—allows the farmers to quickly see what is working and what isn’t. “There’s just much more control with chicken,” he says. Pigs take six months from birth to slaughter, and beef cows take a year and a half, so making changes takes longer and is riskier. Hundley estimates it will be 15 years before half of all US pork is antibiotic-free, and 20-plus years for beef.

And yet there’s starting to be some movement. In February, citing concerns about resistance, the food giant Cargill began to reduce the use of medically important antibiotics by 20 percent in about one-fifth of its cattle. Or take Smithfield Foods, by far the biggest US pork producer, now owned by the Chinese conglomerate WH Group. On its website, the company says it still uses medically important antibiotics “to control, treat, and prevent disease,” but not “to promote growth or for feed efficiency.” Admittedly, it’s hard to monitor why producers dose their livestock with drugs. A 2014 analysis by the Pew Charitable Trusts found that 66 of the 274 medically important antibiotics that the FDA allows to be used for disease prevention can also be useful in growth promotion.

The truth is, antibiotics have been an easy fix for an industry under enormous pressure to produce maximum amounts of animal protein at minimal cost. Levy’s studies showed the dangers of doing that nearly 40 years ago, yet until the recent exception of Perdue, neither regulators nor leading producers chose to act.

Meanwhile, even as global trade has made us more susceptible to superbugs that spring up half a world away, we’ve exported our antibiotic addiction to countries unlikely to exercise caution.

Over the past 15 years, China has been rapidly scaling up its meat production, and farmers there have embraced drugs with little oversight. A 2013 analysis by a Beijing-based agribusiness consulting company found that more than half of all antibiotics in China were used on livestock. That’s a smaller ratio than you’ll find in the United States, but China is expected to double the amount of drugs it feeds to animals by 2030. Last year, Chinese researchers shocked public health authorities when they announced in The Lancet that they had found a strain of E. coli in pigs and humans that had evolved to withstand colistin, a potent antibiotic widely considered a last resort against many multidrug-resistant pathogens. Worse, the gene that allowed the E. coli to shrug off colistin easily jumps to other bacterial species and is “likely to spread rapidly into key human pathogens” like salmonella and Klebsiella—a bacteria that can cause infections like pneumonia and meningitis. The authors warned that these colistin-defying pathogens were “likely” to go global.

And in a particularly perverse disincentive, large pharmaceutical companies are no longer keen to invest in new antibiotics. The reason is that, according to a World Health Organization report, resistance sets in too fast for them to make money off new drugs. So even if consumer pressure forces the rest of Big Ag to follow Perdue’s lead, the industry’s 40-year delay may still end up costing countless lives.

Bob Lawrence of Johns Hopkins says a more optimistic future relies on two conditions: public investment in developing new antibiotics, and a binding global pact to severely ramp down farm antibiotic use. Unless we start rolling out new drugs and using the old ones sparingly, he says, “the genie is so far out of the bottle that we’re facing a rather bleak future.”